Basic Info

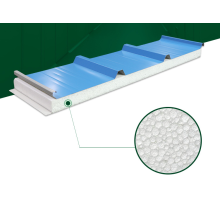

Model No.: YY-001

Click on the follow link to find out more information: https://www.yingyeemachines.com/eps-sandwich-panel-production-line/

Company Info

- Company Name: YingYee Machinery and Technology Service Co.,Ltd

- Representative: Jessica Tian

- Product/Service: Cold Roll Forming Machine , Roof Tile Roll Forming Machine , C/Z Purlin Roll Forming Machine , Shearing Machine , Light Keel Roll Forming Machine , Thread Rolling Machine

- Capital (Million US $): 5000000 RMB

- Year Established: 2015

- Total Annual Sales Volume (Million US $): US$5 Million - US$10 Million

- Export Percentage: 91% - 100%

- Total Annual Purchase Volume (Million US $): US$2.5 Million - US$5 Million

- No. of Production Lines: 8

- No. of R&D Staff: 91 -100 People

- No. of QC Staff: 91 -100 People

- OEM Services Provided: yes

- Factory Size (Sq.meters): 10,000-30,000 square meters

- Factory Location: Bazhou city, Langfang city, Hebei province

- Contact Person: Ms. Jessica Tian

- Tel: 86-18603265521

Premium Related Products

Hot Products

Commercial office furniture Reception corner deskWholesale aluminum galvanized metal steel zinc corrugated roofing sheetConstruction Building Materials AAC Wall PanelsHollow section black annealing ms square steel pipeManufacturers colorful stone coated steel roofing sheetWholesale construction real estate hpl n plywoodConstruction design Prefabricated Hot galvanized Steel Structures workshop/warehouseChina manufacturer food grade 99.2% min na2co3 soda ash light priceInorganic Chemicals liquid sodium silicate pricePopular in Africa Farm Machinery tracked rice combine harvesterChina manufacturer 4mm soft black annealed iron steel wireSteel Profiles galvanized u channel steel sizesChemical yellow powder plastic Azodicarbonamide AC foaming agentMagnesium Sulphate Heptahydrate 2-4mm Food Grade REACH certificateAluminum profile extrusion solar panel frame for solar mounting systemFood Ingredients Food grade baking powder calcium propionate